News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Q & A

Cathodic protection shielding effect

- Author:Libo

- Source:wwww.zou666.com

- Date:2021-08-07

- Click:0

Cathodic protection is a kind of used to prevent the metal dielectric (such as sea water, fresh water and soil medium), the electrochemical corrosion protection technology in the basic principle of this techno logy is to protect metal surfaces exert a certain dc current, make its produce cathodic polarization, the potential of occurring when the metal was a potential value, the corrosion of the anodic dissolution process is effectively suppressed.

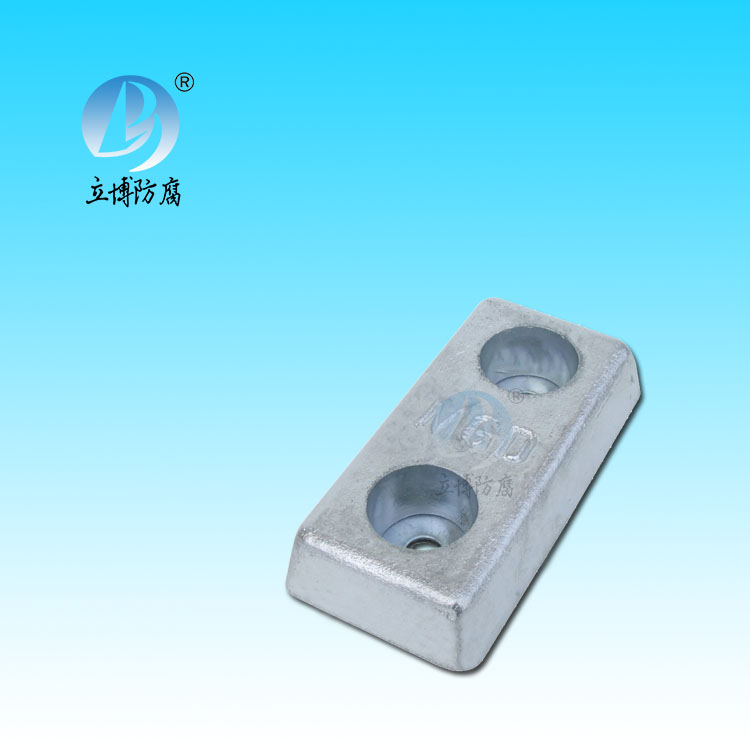

According to different cathodic current, cathodic protection is divided into two sacrificial anode and impressed current method, the former is a more negative potential of metal (such as aluminum, magnesium, zinc, etc.) and the protected metal structure of the electrical connections, through the electronegative metal or alloy melting consumption, provide protection to be protected from electrical current, make the metal structure to be protected. The latter is to convert an external alternating current into a low voltage direct current, which is passed to the protected metal structure through an auxiliary anode, so that corrosion is suppressed.

Whether the sacrificial anode method or the impressed current method, its effective and reasonable design and application can obtain good protection effect.

The combination of cathodic protection and coating can provide the most economical and effective protection for underground or underwater metal structures. A good coating protects more than 99% of the outer surface of the structure from corrosion. Underground or underwater metal structures are usually coated with a protective coating before use to insulate the metal from the dielectric environment. If metal structures can be completely electrically insulated, the formation of metal corrosion cells in the dielectric will be inhibited and corrosion current will not be generated, thus preventing corrosion of the metal.

However, there is no perfect coating. Due to transportation, installation and filling in the construction process, thermal stress and soil stress, the aging of the coating and the existence of tiny pinholes in the coating, there will always be some defects in the outer coating of the metal structure, and these defects will eventually lead to local corrosion of the metal.

The combined application of cathodic protection technology and coating can effectively solve this problem. Cathodic protection on the one hand can effectively prevent coating lesions have corrosion, prolong the service life of coating, coating on the other hand, can greatly reduce the requirement of protection current, improve the protection of current distribution, increase the protection radius, has made it more economic and effective, for the cathodic protection on bare or poor anticorrosion coating of underground or underwater metal structures, Cathodic protection is even the only alternative to corrosion protection.

The cost of the cathodic protection usually only protected metal structure cost 1% ~ 5%, and the service life of the structure can be double or even several times to extend because of this, therefore, the technique to get general recognition of the people, and has set up a ship, in port engineering, Marine engineering, petrochemical, electric power, municipal and other fields to get more and more widely used, promising prospects.

客服QQ

客服QQ